- Plumbing : 0120-4619300-316/+91- 8448793165/ TOLL FREE NO.1800-570-9949 |

- : plumbing@akggroupindia.com

- Electrical : 0120-2973710-713/+91-9818221065 /TOLL FREE NO.1800-570-9949 |

- : electrical@akggroupindia.com

AKG offers an exhaustive range of uPVC pressure pipes & fittings. Pressure pipes are manufactured as per IS 4985:2000 standard and are available in 20 mm to 315 mm sizes in different pressure class. Pipes with both types of joints i.e. solvent cement type and elastomeric rubber seal type joints are available. Varieties of moulded fittings and wide range of fabricated fittings are also available. Moulded fittings are manufactured as per IS 7834:1987 These pipes and fittings are used for variety of applications like, agriculture, irrigation, water supply, industrial process lines, swimming pools and fire fighting mains etc. These pipes are superior to C.I , D.I or R.C.C pipes and offers number of advantages like light weight, easy and fast installation, excellent corrosion and chemical resistance, high flow rates, long life and economy.

| Nominal Outside Diameter (Nominal Size) |

Mean Outside Diameter | Class 1 0.25 Mpa |

Class 2 0.4 Mpa |

Class 3 0.6 Mpa |

Class 4 0.8 Mpa |

Class 5 1.0 Mpa |

Class 6 1.25 Mpa |

|||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| 20 | 20.0 | 20.3 | - | - | - | - | - | - | - | - | 1.1 | 1.5 | 1.4 | 1.9 |

| 25 | 25.0 | 25.3 | - | - | - | - | - | - | 1.2 | 1.6 | 1.4 | 1.8 | 1.7 | 2.1 |

| 32 | 32.0 | 32.3 | - | - | - | - | - | - | 1.5 | 1.9 | 1.8 | 2.2 | 2.2 | 2.7 |

| 40 | 40.0 | 40.3 | - | - | - | - | 1.4 | 1.8 | 1.8 | 2.2 | 2.2 | 2.7 | 2.8 | 3.3 |

| 50 | 50.0 | 50.3 | - | - | - | - | 1.7 | 2.1 | 2.3 | 2.8 | 2.8 | 3.3 | 3.4 | 4.0 |

| 63 | 63.0 | 63.3 | - | - | 1.5 | 1.9 | 2.2 | 2.7 | 2.8 | 3.3 | 3.5 | 4.1 | 4.3 | 5.0 |

| 75 | 75.0 | 75.3 | - | - | 1.8 | 2.2 | 2.6 | 3.1 | 3.4 | 4.0 | 4.2 | 4.9 | 5.1 | 5.9 |

| 90 | 90.0 | 90.3 | 1.3 | 1.7 | 2.1 | 2.6 | 3.1 | 3.7 | 4.0 | 4.6 | 5.0 | 5.7 | 6.1 | 7.1 |

| 110 | 110.0 | 110.4 | 1.6 | 2.0 | 2.5 | 3.0 | 3.7 | 4.3 | 4.9 | 5.6 | 6.1 | 7.1 | 7.5 | 8.7 |

| 125 | 125.0 | 125.4 | 1.8 | 2.2 | 2.9 | 3.4 | 4.3 | 5.0 | 5.6 | 6.4 | 6.9 | 8.0 | 8.5 | 9.8 |

| 140 | 140.0 | 140.5 | 2.0 | 2.4 | 3.2 | 3.8 | 4.8 | 5.5 | 6.3 | 7.3 | 7.7 | 8.9 | 9.5 | 11.0 |

| 160 | 160.0 | 160.5 | 2.3 | 2.8 | 3.7 | 4.3 | 5.4 | 6.2 | 7.2 | 8.3 | 8.8 | 10.2 | 10.9 | 12.6 |

| 180 | 180.0 | 180.6 | 2.6 | 3.1 | 4.2 | 4.9 | 6.1 | 7.1 | 8.0 | 9.2 | 9.9 | 11.4 | 12.2 | 14.1 |

| 200 | 200.0 | 200.6 | 2.9 | 3.4 | 4.6 | 5.3 | 6.8 | 7.9 | 8.9 | 10.3 | 11.0 | 12.7 | 13.6 | 15.7 |

| 225 | 225.0 | 225.7 | 3.3 | 3.9 | 5.2 | 6.0 | 7.6 | 8.8 | 10.0 | 11.5 | 12.4 | 14.3 | 15.3 | 17.6 |

| 250 | 250.0 | 250.8 | 3.6 | 4.2 | 5.7 | 6.5 | 8.5 | 9.8 | 11.2 | 12.9 | 13.8 | 15.9 | 17.0 | 19.6 |

| 280 | 280.0 | 280.9 | 4.1 | 4.8 | 6.4 | 7.4 | 9.5 | 11.0 | 12.5 | 14.4 | 15.4 | 17.8 | 19.0 | 21.9 |

| 315 | 315.0 | 316.0 | 4.6 | 5.3 | 7.2 | 8.3 | 10.7 | 12.4 | 14.0 | 16.1 | 17.3 | 19.9 | 21.4 | 24.7 |

• General Dimensions confirming to IS 7834:1987.

• Wall thickness is designed to meet required working pressure made to close dimensional tolerance.

• Wide range for different applications

Cut the pipe as square as possible. Please ensure that fitment of pipe with socket of fitting is correct.

Total length of insertion of socket shall be marked on pipe(for most of the cases the pipe inserted should be up to the marked line and in no case shall be less than 2/3rd of the pipe end up to the marked line).

The pipe and the socket should be clean and dry. Dust, oil, water, grease etc should be wiped out with dry cloth or cleaner from the surfaces to be coated with solvent cement.

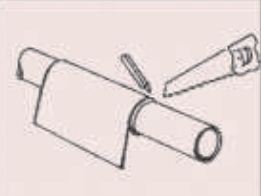

Roughen the outside of the pipe and the inside of the socket using sand paper or piece of hacksaw blade up to the entry mark. Stir adhesive i.e. solvent cement thoroughly.

Apply a thick coat of suitable grade of good quality solvent cement. Using a flat clean brush evenly on the inside of the socket mouth for full length of insertion. And then on outside of the pipe, end up to the marked line.

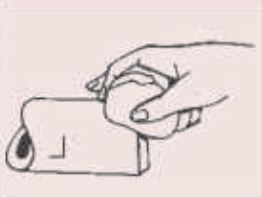

After application of solvent cement, insert the pipe within one minute into the socket. Hold the joint for few seconds and ensure that pipe does not come out of the fitting. Wipe off extra cement. Let it dry. Within 24 hours, your AKG rigid PVC pipes are ready for use.

Clean the inside of socket. Remove all traces of mud, dirt, grease, gravel and clean elastomeric sealing ring.

If pipe need to be cut, it should be cut perpendicular to the axis of the pipe. Then it should be chamfered properly.

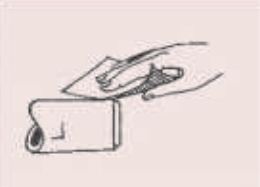

Form the ring into a heart shape by pinching a portion of ring from inside. Insert into the socket and release to seat into the groove.

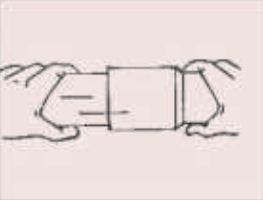

Push the spigot into the socket until it reaches the depth of entry mark, do not over insert. This must be done manually. Insertion of spigot end inside the socket should be at the correct angle.

| Fittings | Pipes | |

|---|---|---|

| Material | Unplasticized Polyvinyl Chloride(UPVC) |

Unplasticized Polyvinyl Chloride (UPVC) |

| Colour | Light Grey | Light Grey |

| Reference Standards | IS 7834 : 1987 | IS 4985 : 2000 |

| Working Temperature of fluids | Upto 60 degree- Continuous Upto 90 degree- Short Time -upto 3 mins |

Upto 60 degree- Continous Upto 90 degree- Short Time -upto 3 mins |

| Working Temperature (gk/cm2) | 4, 6, 10 & 16 | 2.5, 4, 6, 10 & 12 |

| End Connections | Solvent sockets, Threads (For transition fittings) |

Solvent sockets, Rubber Ring sockets |

Agricultural pipes and fittings play a critical role in the irrigation systems used on farms. These agri pipe fittings and agri water pipes are primarily used for transporting water from borewells, canals, and tanks directly to the fields. They ensure efficient water distribution, helping farmers achieve better crop yields. PVC pipes for agriculture are ideal because they reduce water wastage, maintain pressure, and withstand harsh outdoor conditions.

UPVC agri pipes offer several advantages over conventional metal or cement pipes. They are lightweight, corrosion-resistant, and require minimal maintenance, making them ideal for long-term use in agricultural applications. Unlike metal pipes, UPVC pipes do not rust, and unlike cement pipes, they are easy to install and relocate if needed. Additionally, UPVC agri water pipes ensure smooth water flow and greater efficiency for irrigation purposes.

These PVC pipes for agriculture are ideal for both small-scale and large-scale irrigation needs.

AKG’s agri PVC pipes and agri pipe fittings are manufactured following the highest industry standards to ensure durability and performance. Our agri water pipes comply with IS 4985 specifications, which ensures they meet strict criteria for quality, pressure rating, and long-term use in agricultural water distribution systems.

© Copyright- AKG Group of Companies. All Rights Reserved.