- Plumbing : 0120-4619300-316/+91- 8448793165/ TOLL FREE NO.1800-570-9949 |

- : plumbing@akggroupindia.com

- Electrical : 0120-2973710-713/+91-9818221065 /TOLL FREE NO.1800-570-9949 |

- : electrical@akggroupindia.com

AKG uPVC Column Pipes are specially designed for submersible pumps. These uPVC Column Pipes blend the perfect combination of technology and quality that guarantees a long hassle-free performance. These uPVC Column Pipes are a perfect replacement of galvanized steel pipes used for column application. Stringent quality is checked at every stage of production and ensuring the highest standards, which forms the ball mark of these uPVC Column Pipes.

We offer a quality imbibed range of uPVC Column Pipes that have minimum frictional losses and thus save the pumping cost. These are widely reckoned by our clients for its features such as corrosion resistant, easy to install and light weight.

| Size (inch) | Size(mm) | Class | Type | Pressure (kg/cm 2) | Std. Pkg. (No. of Length) | Screen Colour |

| 1 | 33 | ECO | Bell | 12.5 | 35 | Orange |

| ECO | COUPLER | 12.5 | 35 | Orange | ||

| ECO | 15 | 30 | Purple | |||

| MED | 21 | 30 | Green | |||

| STD | 30 | 25 | Red | |||

| 11/4" | 42 | ECO | Bell | 12.5 | 25 | Orange |

| ECO | COUPLER | 12.5 | 25 | Orange | ||

| ECO | 15 | 25 | Purple | |||

| MED | 21 | 25 | Green | |||

| STD | 25 | 25 | Red | |||

| 11/2" | 48 | ECO | COUPLER | 15 | 20 | Purple |

| MED | 21 | 20 | Green | |||

| STD | 26 | 20 | Red | |||

| 2" | 60 | ECO | COUPLER | 8 | 15 | Purple |

| MED | 13 | 15 | Green | |||

| STD | 20 | 15 | Red | |||

| Heavy | 27 | 15 | Black | |||

| 21/2 | 75 | MED | COUPLER | 10 | 10 | Green |

| STD | 16 | 10 | Red | |||

| Heavy | 26 | 10 | Black | |||

| 3" | 88 | MED | COUPLER | 11 | 5 | Green |

| STD | 17 | 5 | Red | |||

| Heavy | 26 | 5 | Black | |||

| 4" | 113 | MED | COUPLER | 10 | 5 | Green |

| STD | 15 | 5 | Red | |||

| Heavy | 26 | 5 | Black |

Bi-axial orientation during column pipe extrusion AKG Group has developed a unique Bi-axial orientation technique used during pipe extrusion, which gives higher drop impact and notch impact strength to the pipes. This orientation technique is a result of constant Research and Development at AKG Group

Patent registered in India The joint of pipes have been specially designed with square threads & rubber rings to ensure proper gripping, no chance of slipping & 100% leak proof joint. These threads are high friction threads on load, which do not open even on constant forward and reverse torque generated by starting & stopping -----. They are made on specially imported CNC machines with special tools to ensure perfect dimensions and good & easy ALL threads checked thoroughly with special gauges to ensure 100% accuracy.

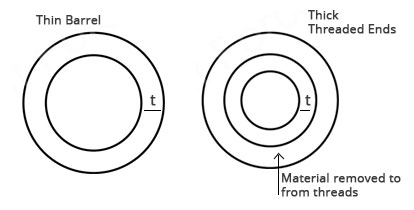

Special thick & thin construction of pipes: This special technique for making pipes thicker in the threading portion end to compensate for material removal due to threads is an innovation made only by AKG.This technique saves on the raw material consumption and at the same time provides much higher strength to the pipes

AKG high tensile. High impact column pipes are made with specially designed formulation, so that pipes are capable of handing both internal hydrostatic pressure as well as huge vertical tensile load on the pipes due to the column and pump weight. The special formulation ensures that the threads do not get brittle and break/chip even after loosening and tightening several times during the life span. Special raw materials are used in very well defined processing techniques to make these pipes.

Borewell column pipes are specialized pipes used to connect submersible pumps to the surface in deep well or borewell applications. These column pipes carry water from deep underground to overhead tanks or direct outlets. A borewell column pipe is engineered to withstand high pressure, pump weight, and water load.

A upvc column pipe is made from Unplasticized Polyvinyl Chloride, a non-corrosive and high-strength material. It's preferred for borewells because it doesn’t rust like metal, is lightweight, easy to install, and lasts much longer, even in hard or mineral-rich water. upvc submersible column pipes also prevent bacterial buildup and scaling.

AKG column pipes are built using high-quality upvc and tested under tough operating conditions. They offer higher torque resistance, better threading, and a unique locking system to prevent slippage. These borewell column pipes are designed to withstand deep installations, pump movement, and water pressure without failure.

AKG offers a wide range of upvc submersible column pipes in different diameters and pressure ratings (Standard, Medium, and Heavy). Whether your borewell is 100 ft or 1200 ft deep, there’s a suitable upvc column pipe variant tailored for your pump and site conditions.

Choosing the right column pipe depends on the borewell depth, motor horsepower, and water yield. Our experts can help you calculate the exact load and suggest the correct grade of upvc submersible column pipes. For deeper wells or higher HP pumps, heavy-duty borewell column pipes are ideal.

Column pipes are connected vertically from the submersible pump upwards using threaded joints. They are carefully lowered section by section into the borewell. AKG upvc column pipes are easy to handle and assemble due to their lightweight yet tough construction.

During installation, ensure the pipes are aligned properly, threads are cleaned, and locking rings are secured. With upvc submersible column pipes, it's essential to avoid dropping or cross-threading, as that can affect performance and lifespan.

AKG column pipes use a specially designed square thread joint with a rubber ring sealing locking system. This prevents joint loosening during pump vibrations or torque, especially important in deep borewells.

AKG ensures every section of the upvc column pipe stays securely in place, even under the continuous pressure and torque of the running submersible pump. This feature makes AKG borewell column pipes ideal for long-term, maintenance-free operation.

A loose joint can cause pump disconnection or even lead to loss of expensive equipment. However, AKG’s double-locking system in their upvc submersible column pipes is specifically designed to prevent such failures, giving you added security in deep installations.

Absolutely. AKG borewell column pipes are tested to handle high depth and load. Whether you're using a 5HP or 20HP pump, there’s a suitable upvc column pipe designed for your needs. Many users trust our pipes even for borewells over 1,000 feet deep.

Yes, that’s one of the key advantages of upvc submersible column pipes. Unlike metal pipes, they don’t corrode or react with minerals in water. This makes them perfect for agricultural, rural, and industrial use in tough water conditions.

When using AKG column pipes, frequent inspections aren’t necessary. If properly installed, these borewell column pipes can last for many years without leaks, slippage, or breakdowns. Still, a routine visual check during pump maintenance is always a good idea.

AKG’s upvc column pipes have a life expectancy of 25 to 30 years under normal operating conditions. Their durability in diverse environments makes them one of the best long-term solutions for borewell column pipe applications.

Yes. While the upfront cost of quality upvc submersible column pipes may be slightly higher than metal, they save you from corrosion, breakage, and frequent replacements. In the long run, AKG column pipes are a far more cost-efficient and reliable solution.

Along with borewell column pipes, AKG also offers a wide range of trusted products, including agri pipes, casing pipe, conduit pipe, copper cable, cpvc pipe, plumbing pipes, swr pipe, upvc pipe, and high-quality wire cables.

© Copyright- AKG Group of Companies. All Rights Reserved.